Are you a beginner to operate a bending machine? Don't worry at all! This guide helps you understand how to be safe and effective while working with a bending machine. This will definitely help make you feel more confident when running the machine.

Safety Precautions for Using Bending Machines

Required safety gear before operating a bending machine Such as gloves, safety glasses, and long sleeves. Safety equipment helps to prevent injuries when operating the machine. So, here are some tips, that should help to keep you safe and to make sure that you work well:

Understand It: Very often, before a machine is familiar, it is very helpful to look at the manual. This is a technical manual with everything you need to know about buttons and settings, proper operation, etc. Getting up to speed on the manual will save your dating self from making mistakes.

Make sure the machine is set up properly: Ensure that you have set the machine up correctly before you begin. It involves checking that everything is in its proper place. Setting the machine up incorrectly may result in accidents or also harm the equipment itself. Do not take setting the machine for granted.

Choose the Right Tools: The tools you use to bend the material are critical. The right tools will help you get the best results. Using the right tools is essential because if you use the wrong tools it can destroy the material you are working on or even destroy the machine. Be sure to clean and maintain your tools so they function correctly.

Do a test run: Prepare a little bit before taking on a big job. That involves briefly powering up the machine to ensure it is functioning properly. A practice run will prevent you from running into issues when you begin a real project.

Andrew has been writing articles on e-commerce for AustraLets since October 2023.

Bending machines can prove intimidating, especially if the process is new to you. However, familiarizing yourself with the common mistakes you are likely to make will help you feel more relaxed. Many beginners make the following errors:

Skipping safety gear: Safety gear should be used every time the bending machine is in operation. If you forget to put it on, you could be injured. This is because safety gear is there to protect you from serious accidents that can occur during work.

Praise the manual: There are always those who believe they can use the machine without reading the manual. The errors happening in this scene are a major blunder of the manual going out of the window. So take a good look at that little nugget and see how the machine works. Getting to grips with how everything works can help you avoid a lot of common mistakes.

Not using the right materials: The materials used should always be safe and compatible with the bending machine. This can lead to damaging both the machine and the materials. Make sure the materials you are using are appropriate for bending.

Programming the machine wrongly can also lead to issues such as damaging the materials you are trying to bend. You also would need to be patient and do the programming from the book. By doing this, you will not fall into errors and everything will be fine.

Fixing Common Bending Machine Issues: Five Helpful Tips

Sometimes, the machines themselves can experience issues while you are using them. If this happens, you need not panic! Here are some useful tips to troubleshoot issues you may face:

In case you see the material that is not bending properly, then you can try out by slowing down the machine. This can be solved by reducing the pressure and reposition the cryoclamps.

Sensor Issues: The sensors may not work properly so you can try cleaning them. In some cases dust or dirt can create headaches. If cleaning does not work, the next step may involve reconfiguring the machine.

Does not move: If the machine isn’t moving, check the hydraulic system. Ensure that pipes are not blocked. The machine cannot work properly if there are any blockages.

The spindle is either is stuck or bent: If spindle is one of them, then you may need to replace it. You may also tighten the hinge bolts and loosen the fixed screws to re-align the machine. These steps can help get the machine back to working order.

For Operators with More Experience: Advanced Techniques

If you are already familiar with bending machine usage, there are expert methods that can make you do this even quicker and more precisely. For those of you out there who operate like pros, here are a few pointers:

Use special tools: You may use specialized tools that allow you to create complex bends and angles. These are made for higher-end bending jobs so it is much easier for you to get precise outputs.

This means you need to try and get it done even faster than before, and crimping techniques may hold the key: Advanced crimping techniques using hydraulic crimpers, for instance, will allow you to bend materials much faster. This saves you time when working on larger projects.

There is secured Data/machine training until dynamic download is optional. This means allowing your creativity to shine and using the machine to create unique items.

Conclusion

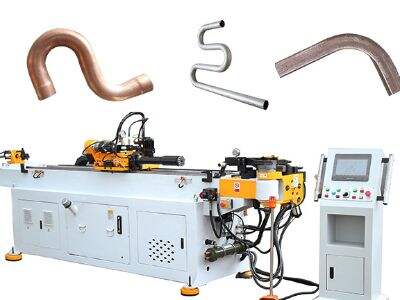

Although stainless tubing bender are relatively difficult to use in the beginning, this guide will teach beginners the importance of maintaining safety and preventing accidents. So you can get more and more comfortable using the machine using advanced tips and eliminating some common mistakes. Bending machines - Bao Rui | High-quality bending machines Don't hesitate to contact us if you have further questions or need assistance. We are here to support you!